G-M Enterprises secures multimillion dollar order from global MIM supplier

January 20, 2021

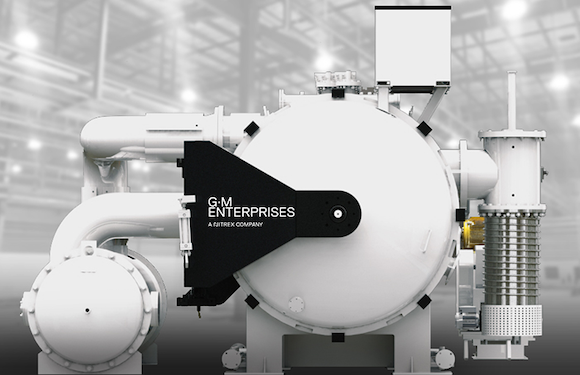

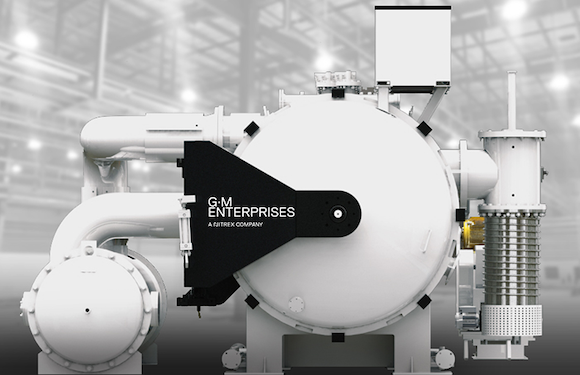

G-M Enterprises, a Nitrex company in Corona, California, USA, has received a multimillion-dollar order from a global manufacturer of Metal Injection Moulding (MIM) products to supply two large horizontal vacuum furnaces.

These 2-Bar vacuum sintering furnaces feature a work area of 900 x 762 x 2100 mm (36 in x 30 in x 84 in), 4400 lb weight capacity, a maximum operating temperature of 1430°C (2600°F) and uniformity of +/- 5.5° (10°F).

Integral to the vacuum system configuration is an efficient multistage debinder trap system, designed to thermally extract binder from the parts. Sintering and debinding occur in a single cycle using a system design that is optimised to handle the maximum load capacity the furnace is designed for.

Consequently, there is never a need to operate below the rated load capacity to achieve the required part quality. The high-temperature sintering process also ensures a high-quality finished part surface in terms of density, porosity, mechanical resistance and aesthetics.

“This latest order comes from a customer we have had a strong cooperation with, and which will be part of a series of multiple furnaces provided by G-M Enterprises over the past decades. G-M Enterprises was carefully selected because of our ability to meet the customer’s large-scale design requirements and to optimise the furnace performance, our competitive lead time, as well as the predictable and repeatable metallurgical results,” stated Michel Frison, VP Global Sales, Nitrex and G-M Enterprises.

G-M Enterprises has over forty years of experience in the thermal processing industry and currently functions as a leading manufacturer of high-temperature vacuum furnaces and hot zones developed and used for a variety of heat-treating applications for a variety of industries, including aerospace, nuclear, power turbine, medical, tool and dies, MIM and Additive Manufacturing, among others.

The first of the 2-Bar vacuum sintering furnaces will be delivered this year, with the second scheduled for commissioning in March 2021.